The Habitat

Powered by Sprout AI

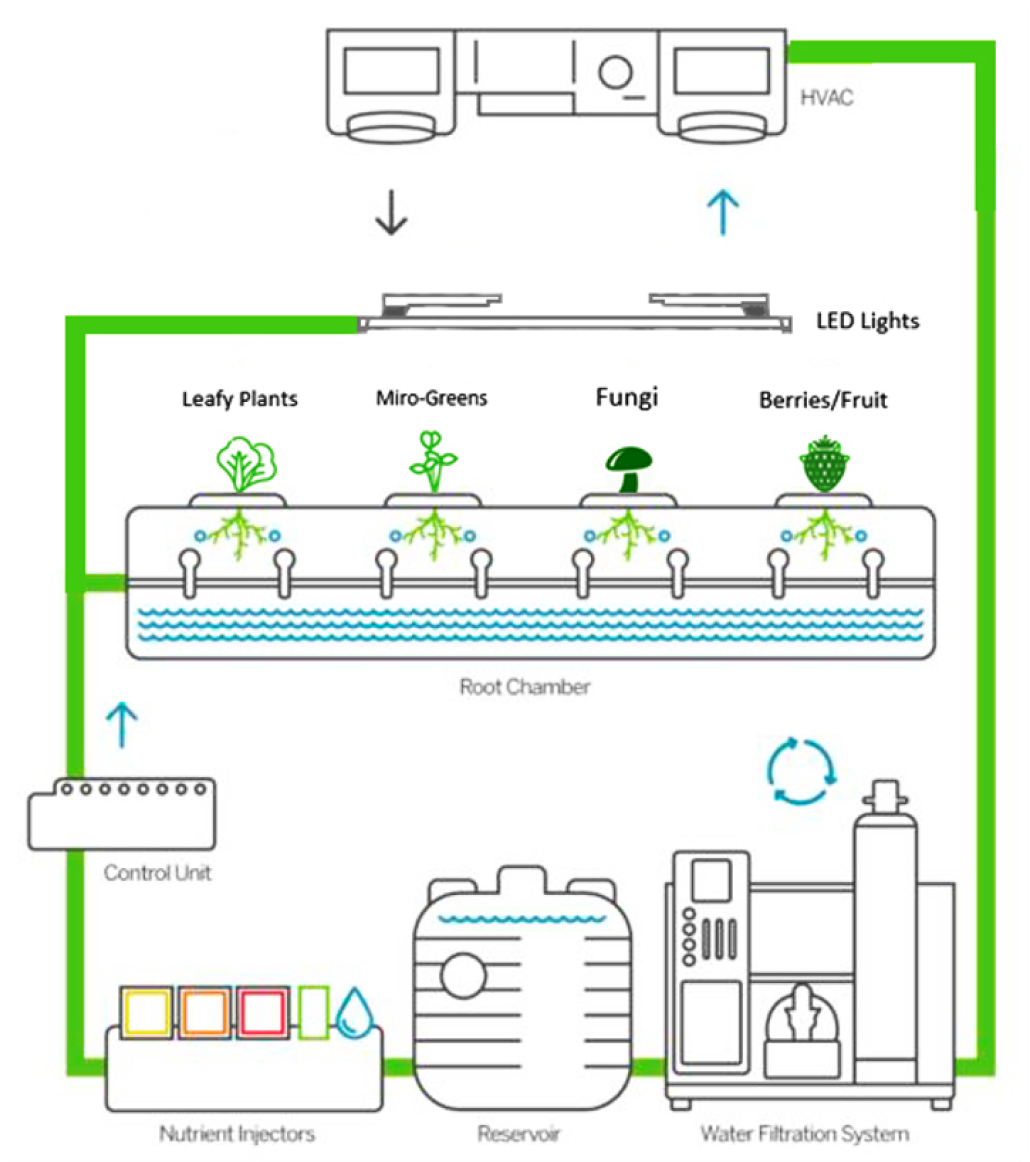

Sprout AI’s cultivation technology is contained within a sealed “habitat” that includes LED lighting to minimize power consumption, advanced air filtration and HVAC, as well as a water recycle system recovering 100%.

Each habitat is self-contained allowing for staggered growth plans, which results in greater labour efficiency.

The separate habitats also mitigate external and cross-contamination risk and allow for multi-crop farms which can be scheduled to ensure continual harvest every day.

Fogponic Driven: Sprout AI uses fogponics whereby the root is suspended in the air and misted with purified, nutrient-rich water. fogponics uses the least amount of water (vs hydro, aquaponic, and areoponic), has the lowest risk of plant contamination, and provides the roots of the plant with the most optimal way to absorb nutrients.

The AI Behind Sprout AI

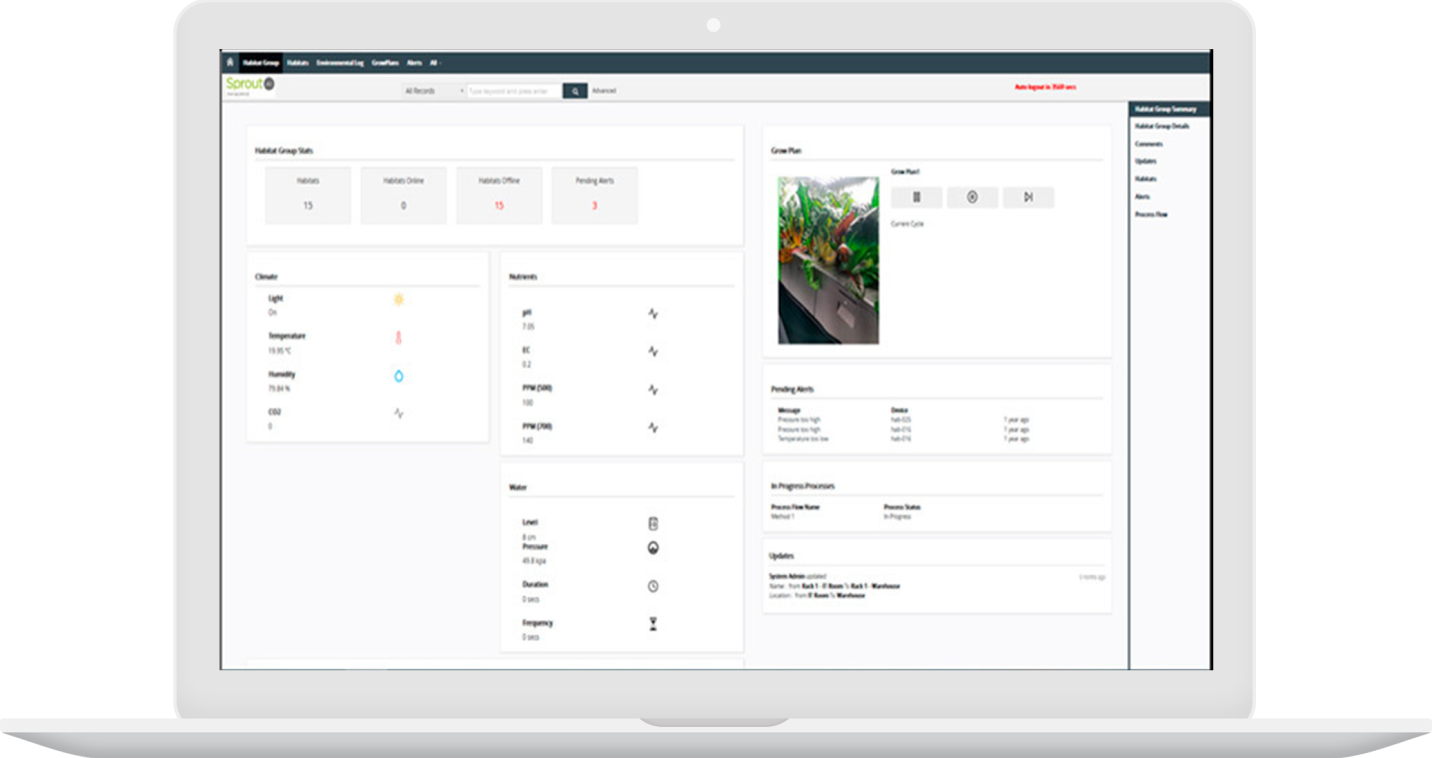

Sprout AI’s module learns over time to optimize grow conditions. Significant data collection from habitats across the world further intensifies the machine learning capabilities.

Scalable Habitats

The habitats are moveable, scalable and modular to meet demand, resulting in reductions in set-up time and capital cost.

Sizing

One habitat is a 10’ x 5’ x 6’ high unit, one row is 5 habitats, one rack is 15 habitats, and one stack is 75 habitats.

Rolling Racks

Reduces fixed aisle space, allowing for a substantial increase to the cubic cultivation area.

Habitats Anywhere

Virtually Any Vacant Indoor Space

The Sprout AI Habitat can be set up in any structure around the world that meets, or can meet, food grade requirements, mitigating the need for a special building to be constructed, and can take advantage of virtually any vacant indoor space.

The Output

Up to 42” high versus 4 - 6” high

Sprout AI's habitats are plant agnostic, and designed to easily accommodate different plant densities of up to 600 plants per habitat. Sprout AI provides an easy to follow plant placement map to optimize plant density.

Micro Greens: Oregano, basil, rosemary, chives, garlic